During the water treatment process, it will produce different kinds of moistured sludge. The sludge dewatering system is mainly used for reducing water content, moisture rate and sludge volume. This will bring convenience for next sludge treating process.

- +86-0510-85950018

- sales@wxgyhj.com

1. Introduction

During the water treatment process, it will produce different kinds of moistured sludge. The sludge dewatering system is mainly used for reducing water content, moisture rate and sludge volume. This will bring convenience for next sludge treating process. Generally, the sludge dewatering system can be divided into belt press, plate-and-frame filter press, screw press. Currently, belt press has been widely applied in sludge dewatering process. Due to its large water consumption, high requirements of handling problems, screw press is a new kind of sludge dewatering system with energy conservation,stable and high automation.

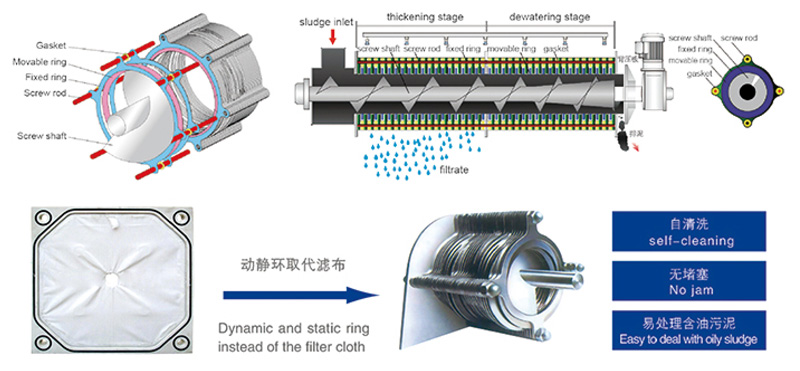

2. Working principle

The main body of screw press consists of several fixed rings and movable rings. The screw shaft runs through these rings, finally forming a filter unit. The former stage is thickening stage and the end is dewatering stage. Due its unique structure, it has replaced the traditional filter cloth and centrifugation.

3. Features

1) simple treatment process, high efficiency of dewatering and thickening, low investment cost

2) Dosing with PAM agent for easy dewatering

3) High degree of automation, wide application

4) Continuous operation,no secondary pollution

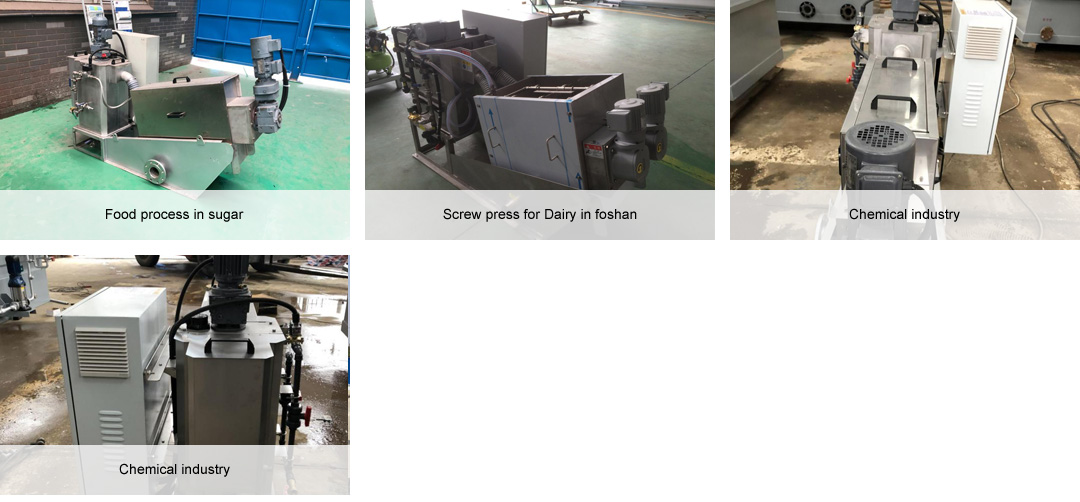

4. Application

It is widely used in municipal sewage, food, beverage, slaughter and breeding, printing and dyeing, petrochemical industry, paper-making, leather, pharmaceutical and other industries.Technical data sheet.